Global Engineered Solution Provider of Mechanical Components & Assemblies for OEMs

Dynatool is an ISO 9001:2015 certified manufacturer dedicated to developing products that perform better, look refined, and are optimized for cost-efficient production.

Our team of engineers combines technical expertise with forward-thinking design. We specialize in Pro-E and SolidWorks modeling, rheocasting and die casting, machining, testing, and full mechanical assembly. From concept to production, Dynatool is your trusted partner for complete product development.

Dynatool Industries delivers end-to-end engineering and precision manufacturing from our facilities in Montreal and Asia. With over three decades of experience producing high-integrity cast components and complex assemblies, we help businesses reduce lead times, optimize costs, and bring high-performance products to market faster.

Our Core Capabilities

Product Development & Engineering

Conceptual design, DFM, casting simulation, and 3D CAD/FEA

Rapid Prototyping

Additive manufacturing for functional design validation

Die Casting & Rheocasting

High-strength aluminum and zinc castings

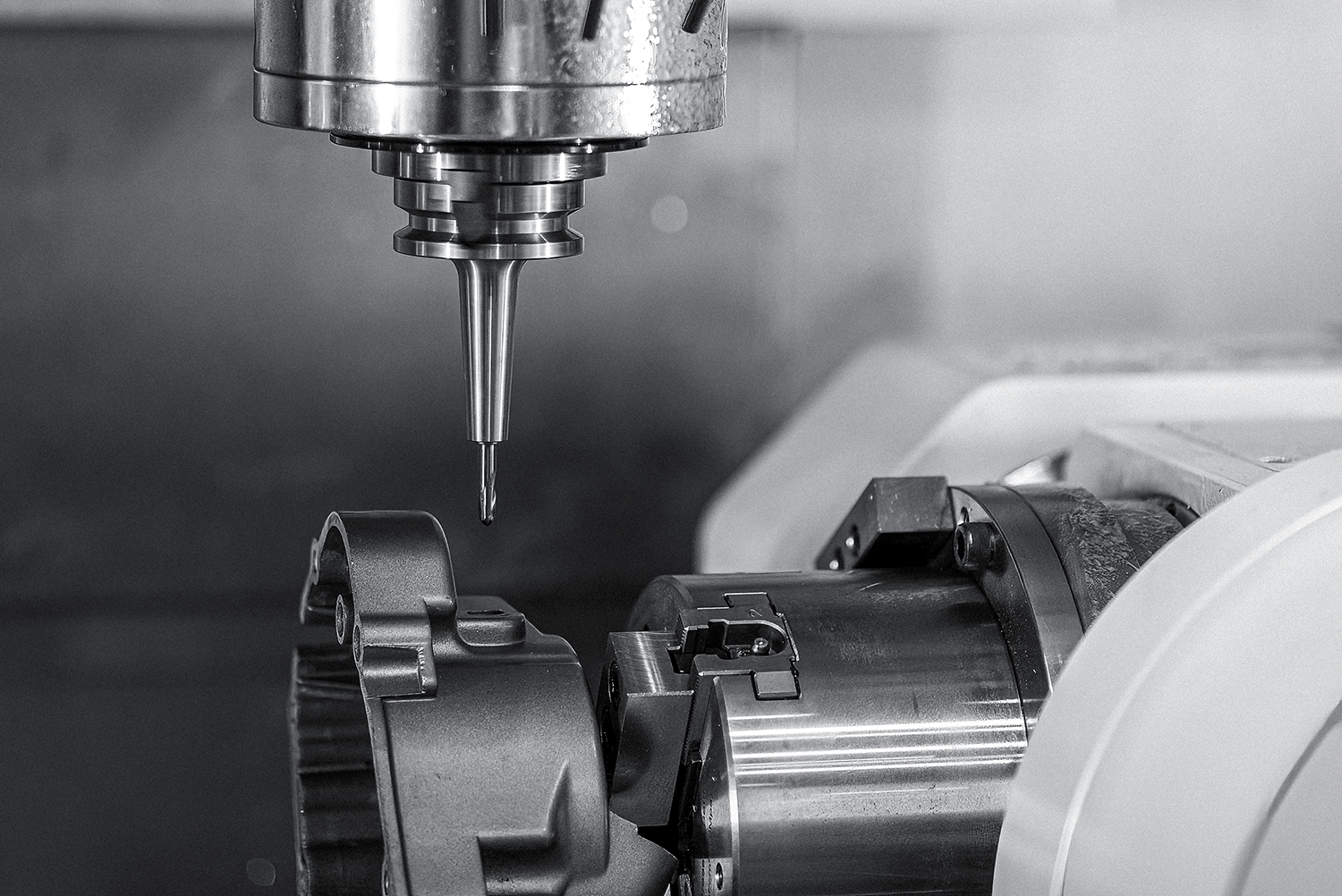

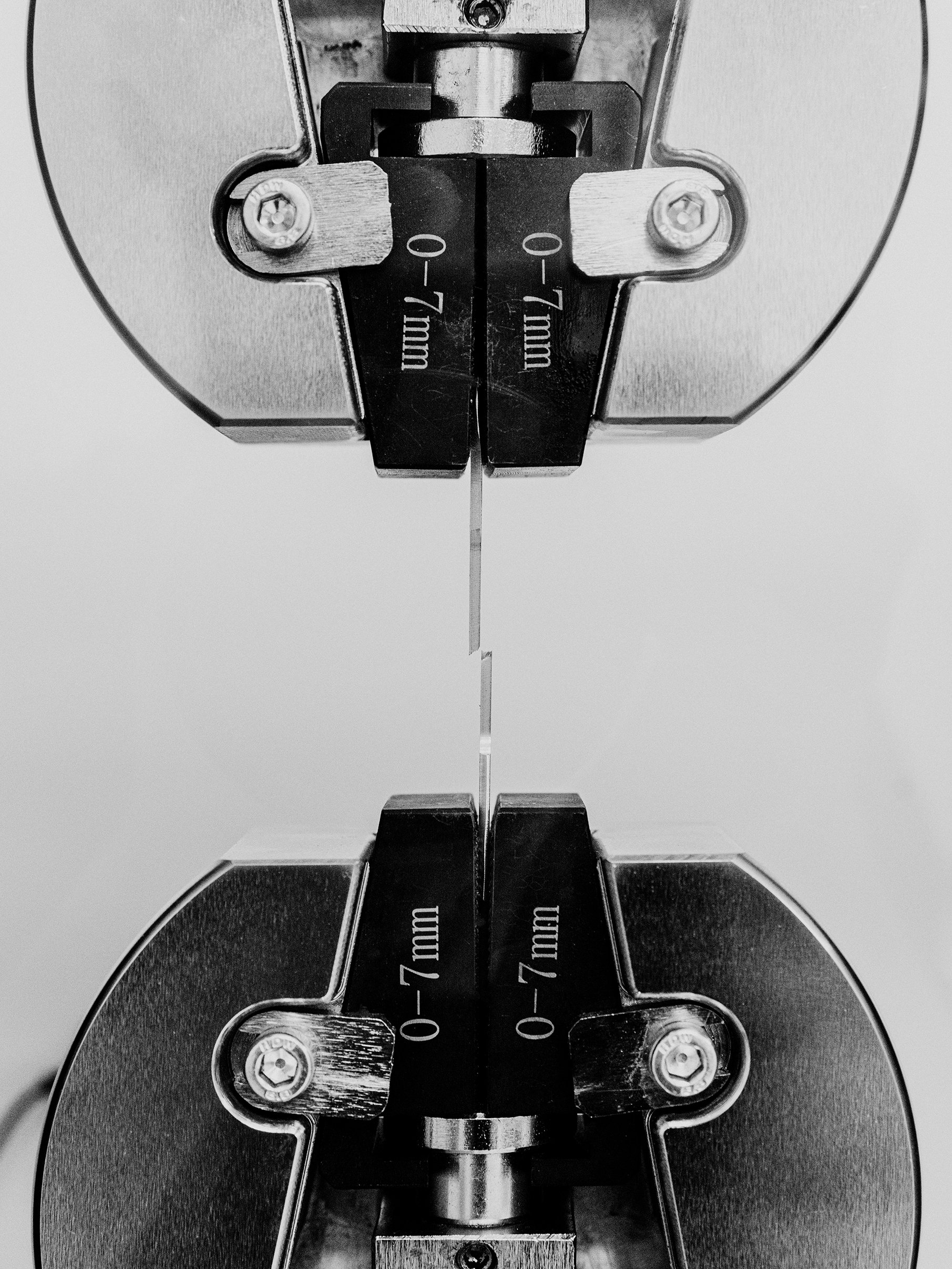

CNC Machining

Tight-tolerance components manufactured to spec

Surface Treatment & Heat Treatment

Durable, high-quality finishes

Full Mechanical Assembly

Turnkey systems ready for integration

Why Companies Choose Dynatool

-

As an ISO 9001-certified manufacturer, Dynatool applies rigorous process controls and verification at each step, from design and rheocasting through machining and final assembly, so complex mechanical assemblies arrive on spec, on time, and production-ready.

-

Dynatool combines local Canadian engineering and program management with a global network of manufacturing partners in North America and Asia, giving customers responsive support and scalable production under one coordinated team.

-

With decades of specialized work in telecom infrastructure, transportation systems, and medical components, Dynatool understands each sector’s performance and compliance demands and designs assemblies that meet those requirements in real-world use.

-

Dynatool’s rheocasting capability produces lightweight aluminum components with high structural integrity and excellent thermal performance, enabling thinner walls, lower porosity, and stronger parts for demanding telecom, EV, and transportation applications.

-

Dynatool can hold local inventory and manage stocking programs close to your production sites, smoothing demand fluctuations, shortening lead times, and reducing the risk of line‑stopping shortages in your supply chain.